sheet pile thickness testing|sheet piling dimensions and properties : distributors Many piling design codes allow for reduced safety factors on the piles capacity if the strength of the pile is verified through appropriate methods of pile testing. This can mean that the cost of the site-testing could be more than covered by costs saved on pile length, diameter and reinforcing bar.

webSão Lucas Laboratório - Resultado online. Resultados Online. Para garantir a comodidade! A ferramenta de Resultados pode ser acessada de qualquer lugar e em qualquer navegador com internet. E os recursos não .

{plog:ftitle_list}

16 de ago. de 2019 · It is cross platform with Xbox one and Windows 10 version, so technically it is, but those are the only two platforms that can play together. Steam can play with Steam. PS4 can play with PS4. Xbox One can play with Windows 10 Version (Found in Microsoft Store) Xbox One can play with Xbox One

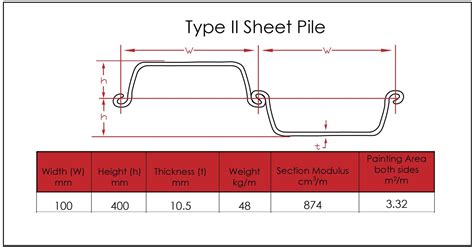

Metal Thickness Testing The thickness of the steel piles was measured using ultrasonic test methods. Sheet pile thickness tests were made by mechanically removing rust deposits and .For the structural analysis of sheet piling, the primary object is to analyse failure due to excess bending moment and stresses. Most of the analysis of cantilever and anchored walls involve the computation of pure bending. For the case of .Atlanta PVC Sheet Pile Cap 290 Unit Test Method Specification Section Width (W) mm 458 Section Depth (D) mm 254 Thickness (T) mm 10.5 Weight kg/m 11.60 Standard Length (L) m 12.00 Moment of Inertia cm4/m 19,300 Section Modulus cm3/m 1,480 Ultimate Moment kg-m/m 6,780 Allowable Moment kg-m/m 3,39010.1 Test-driving 10.2 Driving in restricted headroom 10.3 Driving under water 10.4 Verticle loads . Technical European Sheet Piling Association (TESPA) manual on the installation of steel sheet . tion properties of a pile are based upon: the thickness of the steel; the depth and width of the section; and its designed shape. .

Three 、 piling of steel sheet pile. The piling place of steel sheet pile should be chosen on the flat and firm site which is not to be pressed, but will have large subsidence and deformation, and it is easy to be transported to the pile driving construction site. Pile up should pay attention to:

Many piling design codes allow for reduced safety factors on the piles capacity if the strength of the pile is verified through appropriate methods of pile testing. This can mean that the cost of the site-testing could be more than covered by costs saved on pile length, diameter and reinforcing bar.Sheet pile walls may be cantilever or anchored walls. . and steel grades. Z-type piles and Amer-ican Society for Testing and Materials International (ASTM) A572, Grade 50 are the most common. Sheet pile may be hot-rolled or cold-rolled piles (fig. . a wall thickness of 6 to 12 inches and widths of 30 toThis stratum is 10 feet in thickness, and was encountered at a depth of 10 feet below the existing surface grade elevation. It is a . 35 feet as determined in the test borings. The steel sheet piling was driven through the decomposed shale bedrock. Competent bedrock was determined based upon refusal of the sheet piling to The article, sheet pile retaining wall discuss the stability design of sheet pile retaining wall. Timber Piles. . the pile testing will be simulated with software and the falling height of the hammer is decided in such a manner that it will not generate tensile stresses than that can be allowed or that can carry by the pile reinforcements.

DESIGN OF SHEET PILE WALLS Distribution Restriction Statement Approved for public release; distribution is . ongoing research, prototype, model sheet pile wall testing and development of more refined analytical models, this manual is intended to provide examples and procedures of what has been proven success- . I-Walls of Varying Thickness . expressing the result of a test, shall be rounded off in accordance with IS : 2-1960”. The number . 4.1 Steel sheet piling sections conforming to this 6.3 Tolerance on Mass - The tolerance on mass . within the minus range of thickness tole- 6.2.1 Interlock shall meet the following essential rance, and requirements: b) The ground portions .steel sheet piling system can be designed to provide a so-lution. For some projects, the best system for the job in-cludes some supplemental corrosion protection. In many . Loss of Thickness Due to Corrosion for Steel Sheet Pilings ( Ref 4) A 4. TABLE 1. A. Values are provided for general guidance only. Local knowledge may lead to the use of . Static loading test of a pile in the horizontal direction and dynamic loading test of a 3×3 pile group in the same direction were carried out. The small steel piles used in these tests were 152 .

Drop Dart Impact Tester distribution

In marine construction environments, steel sheet pilings are exposed to a host of natural influences that can impact their useful service lives. Corrosion represents one inevitable factor which engineers and marine contractors must consider when designing, installing, or working around these structural sections. Because damage stemming from corroded steel can . Learn more about the benefits and technical aspects of sheet piling, from the design of sustainable and resilient sheet pile walls, to digitalization and installation. Read more. Sustainable steel foundation solutions. Learn about steel sheet piles and the circular economy : Reduce - Reuse - Recycle.B.4.2 Type of welding. Welds D.1 and D.2 are intermittent welds with an effective weld thickness a eff of 5 to 6 mm, the total length of the intermittent weld being 30 % of the pile length, meaning 3 welds of 100 mm each per metre.. When there exists a possibility of serious corrosion, a continuous sealing weld may be necessary between the intermittent welds.

K007en_STEEL SHEET PILES - Nippon Steel CorporationThe thickness of the sheet pile web and interior and exterior flange faces was also recorded at these nine test locations (see Appendix F, Ref. 1). . memorandum "Wyckoff Sheet Pile Wall - Thickness Testing" Appendix F, Reference 1. - The height and length were measured with a tape measure to the nearest 1/16th of an inch. 2. Obtain the moment .the test pile performance to be monitored throughout the full duration of the test. 2.3 Load application limits The maximum test load to be applied must be agreed in advance so that the test pile, pile cap (if required) and the load testing equipment (reaction piles/kentledge/

JIS A 5523 (hot-rolled steel sheet piles for welding) and JIS A 5528 (hot-rolled steel sheet piles). Tolerances for shapes and dimensions Standards Chemical composition Mechanical properties [Remarks] Deflection is defined as being parallel to the sheet pile wall, and camber perpendicular to the sheet pile wall. Thickness Deflection Camber Item

This is based on ARCELOR design manual as per Ref. [4]. Then, the thickness of the sheet pile corresponding to the tension calculated for the joint is extrapolated. Monitoring of the Corrosion on a Steel Sheet-Pile Marine Breakwater by Systematic Thickness Measurements The safety factor used in the formulas was 1.5.Philippines provider of imported steel sheet piles, vinyl PVC sheet piles, pipe piles, bridge structure, preengineered steel buildings, marine fender & bollards . Steadfast, Committed, Standing the Test of Time. ESC Group Since 1986: Forging Onward with its Position as Global Engineered . The profiles vary from 3mm to 22.0mm thickness and .Sheet pile wall types, construction methods, advantages and disadvantages are described in this article. . This type of pile is made with three planks, 5 cm, 8 cm or 10 cm in thickness. The planks are nailed together with the middle plank offset forming a tongue on one edge and a groove on the other. The planks are connected by using a pair .•Cold Form Sheet Piling •Combined Wall Systems •Pipe •Micropiles •Cold Rolled Threaded Bar •DCP & Strand Anchors . •Corrosion Test •Wrightsville Beach, NC •5 Year & 9 Year Samples •Carbon & Ni-Cu-P Steel . •Loss > Thickness → End of Life . Design Control •What is Controlling your Design •Strength •Stiffness

sheet pile sections. They are located in the centerline of each section. Y = 6" (152.4 mm) Ø = 21/2" – 25/8" (63.5 mm – 66.7 mm) Z-Sections (NZ, PZ, SKZ/SCZ) Straight Sections (PS) Steel Sheet Pile Steel sheet piles are interlocking, corrugated structural sections that are used to form a continuous retaining wall to retain soil or water.Additionally, the asymmetrical shapes typically seen for FRP sheet piles make the testing of these materials more difficult than for many other commonly produced structural shapes [19]. . The result is a wall with a better finish and less variability in thickness and less risk of soil inclusions and loss of cover to the reinforcement. concrete filled steel tubes (CFSTs), and sheet piling. The design wall, flange, and web thickness, as applicable, for structural steel sections shall be reduced for corrosion over a 75-year minimum design life. The remaining steel thickness at 75 years shall be sufficient to . CALTRANS Test 422 (soil and water chloride content)

sheet piling sizes and dimensions

sheet piling dimensions and properties

Make PZC sheet piling your first choice for its unmatched combination of drivability, ruggedness, and strength to weight efficiency. The following PZC sections are part of the Guide Specification published by the U.S. Army Corps of Engineers. PZC SHEET PILING PROPERTIES 12.56" 319 mm 27.88" 708 mm 0.375" 9.5 mm 0.375 9.5 mm " 9. PZC 13 42˚water levels on the two sides of the structure such as a dam or a sheet pile as shown in Fig. 1. Whenever there is seepage (e.g., beneath a concrete dam or a sheet pile), it is often necessary . Permeability of a coarse grained soil can be determined by a constant head permeability test (AS1289.6.7.1-2001; ASTM D2434), and in a fine grained .

Heat Shrink Tester distribution

Lista de Jogos de Tiro em Primeira Pessoa (77) 2009. Jurassic: The Hunted. 2008. Call of Duty: World at War - Final Fronts. Secret Service. Civil War: Secret Missions. .

sheet pile thickness testing|sheet piling dimensions and properties